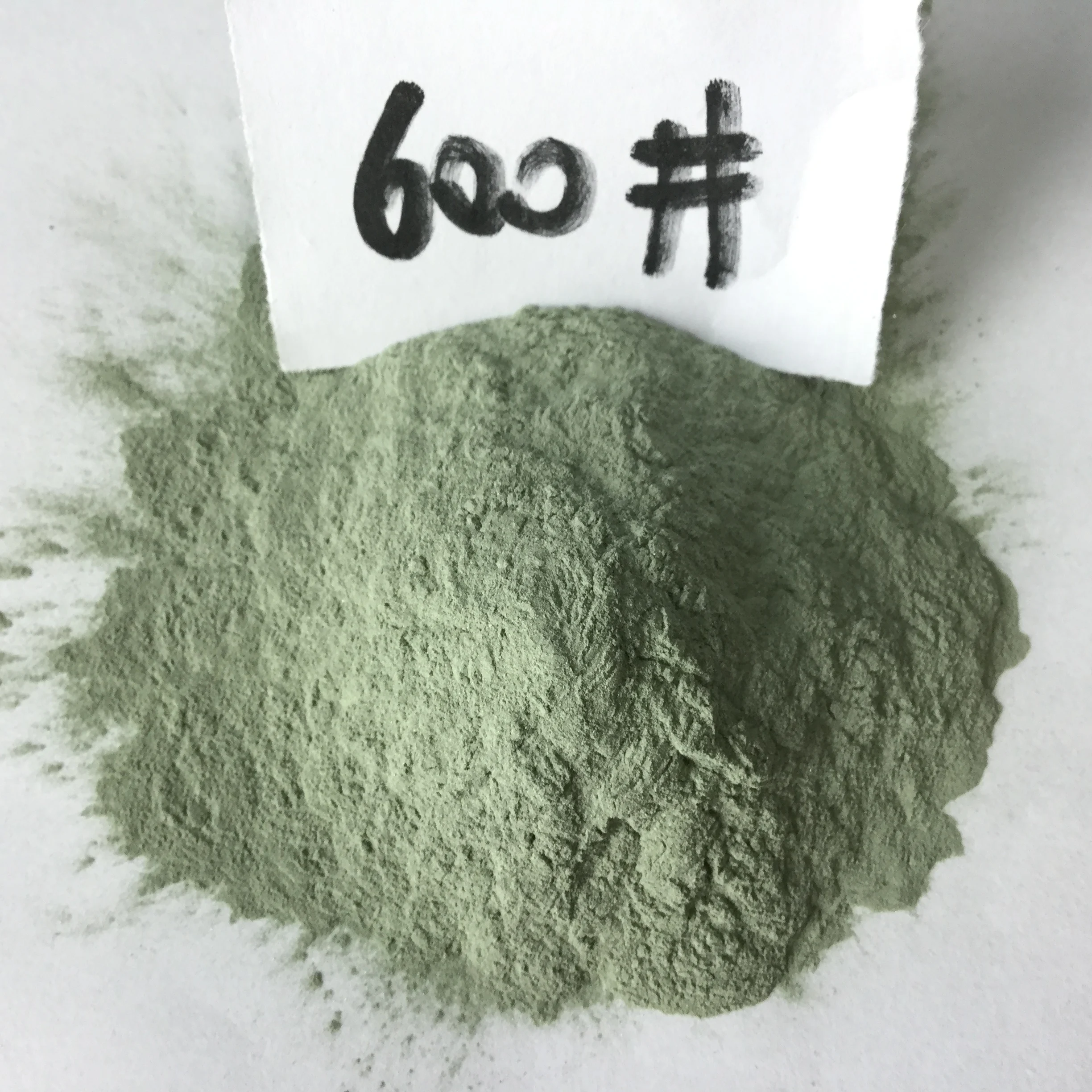

Green Silicon Carbide Green Diamond 600 Mesh for Graphite Blades

Green Silicon Carbide Green Diamond 600 Mesh for Graphite Blades—-Product introduce

Green SiC is an extremely hard (Knoop 2600 or Mohs 9.4) man made mineral that possesses high thermal conductivity (100 W/m-K).

It also has high strength at elevated temperatures (at 1000°C, Green SiC is 7.5 times stronger than Al2O3).

Green SiC has a modulus of elasticity of 410 GPa, with no decrease in strength up to 1600°C, and it does not melt at normal pressures but instead dissociates at 2815.5°C.

Green Silicon Carbide Green Diamond 600 Mesh for Graphite Blades—Physical and Chemical Composition

Physical Properties | |

Hardness: Knoop | 2600 |

Hardness: Mohs | 9.4 min |

Melting Point | 4712°F (2600°C) |

Thermal Conductivity* | 210 btu/hr/ft2/in/°F at 400 °F |

Specific Gravity | 3.2 g/cm3 |

Particle Shape | Blocky, Sharp |

Color | Green |

Typical Chemical Analysis | |

Total SiC | 99.05% |

Total SiO2 | 0.2% |

Total Si | 0.03% |

Total Fe | 0.04% |

Total C | 0.1% |

The application of silicon carbide in the graphite industry is mainly reflected in the following aspects:

Graphite electrode production

Silicon carbide is used as a reinforcing material to improve the strength, heat resistance and conductivity of graphite electrodes, making them perform better in high-temperature arc furnaces.

Graphite crucible manufacturing

Silicon carbide is used as an additive to enhance the high temperature resistance and thermal shock resistance of graphite crucibles and extend their service life.

Graphite mold manufacturing

Adding silicon carbide to graphite molds can improve their hardness, wear resistance and corrosion resistance, and is suitable for high temperature and high pressure environments.

Graphite lubricant

Silicon carbide is used in graphite lubricants to improve lubricity and wear resistance, and is suitable for lubrication needs under high temperature and high speed conditions.

Graphite composite materials

Silicon carbide is combined with graphite to form a composite material, which has the lubricity of graphite and the hardness and wear resistance of silicon carbide. It is widely used in mechanical seals, bearings and other fields.

Graphene preparation

Silicon carbide is used as a substrate material for the epitaxial growth of graphene to help prepare high-quality graphene.

Graphite product surface treatment

Silicon carbide is used for surface coating to enhance the wear resistance, corrosion resistance and oxidation resistance of graphite products.

Graphite heating element

Adding silicon carbide to graphite heating element can improve its high temperature resistance and oxidation resistance and extend its service life.

In summary, the application of silicon carbide in the graphite industry is mainly focused on enhancing material performance, extending service life and improving product quality.

Typical Size for Green silicon carbide polishing powder

Section Sand:0-1mm, 1-3mm, 3-5mm, 5-8mm

F-macrogrit-Sizes-bonded F12F14F16F20F22F24F30F36F40F46F54F60F70F80F90F100F120F150F180F220

JIS-microgrit-Sizes-bonded

240#280#320#360#400#500#600#800#1000#1200#1500#2000#3000#4000#6000#

8000#10000#