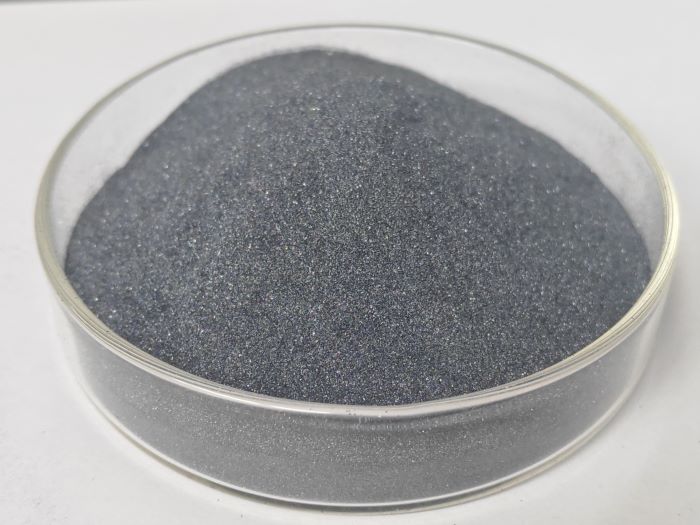

Black silicon carbide 53С 0-0.5 mm SiC 95% 97% 98%

Product Introduction

Black Silicon Carbide 53С 0-0.5 mm is a versatile, high-performance abrasive grain available in three distinct purity grades: 95%, 97%, and 98%. This product line combines a precisely controlled particle size distribution (0-0.5mm, classified under the 53С standard) with options for chemical purity, allowing for tailored solutions across a broad spectrum of industrial applications.

Produced in electric resistance furnaces, Black Silicon Carbide (SiC) is renowned for its exceptional hardness (9.25 on the Mohs scale), sharp fracture, high thermal conductivity, and chemical stability. The 53С specification ensures consistent granular composition for reliable and predictable performance in every batch.

Key Features & Advantages:

Purity Selection: The trio of purity levels (95%, 97%, 98%) provides optimal cost-performance matching. Higher purity grades (97%, 98%) contain minimal metallic impurities, making them ideal for advanced applications where contamination or maximum performance is critical.

Optimal Grain Size: The 0-0.5mm (or 0-500 micron) range offers an excellent balance of cutting aggressiveness and the ability to achieve a refined surface finish, suitable for both bulk removal and precision work.

Superior Material Properties: All grades provide excellent hardness for cutting hard, brittle materials, outstanding thermal shock resistance, and effective heat dissipation.

Application Versatility: The combination of size and selectable purity makes this product suitable for abrasive, refractory, and functional applications.

Primary Applications:

Abrasive Tools & Blasting: Manufacturing of resin-bonded grinding wheels, abrasive bricks, and use in sandblasting for surface preparation (especially 95% grade).

Refractory & Ceramic Additives: Enhances strength, toughness, and thermal shock resistance in advanced castables, ceramics, and kiln furniture. Higher purity grades (97%, 98%) are preferred for high-performance technical ceramics.

Wire Sawing & Lapping: A key abrasive material in slurry for cutting and precision lapping of semiconductor materials, quartz, and crystals (typically requiring 97% or 98% purity).

Metallurgical Additives: Used as a deoxidizer and carburizer in iron and steel production.

This Black Silicon Carbide 53С series empowers manufacturers to select the precise grade that aligns with their technical requirements and economic considerations, delivering performance and reliability in demanding environments from foundries to high-tech industries.