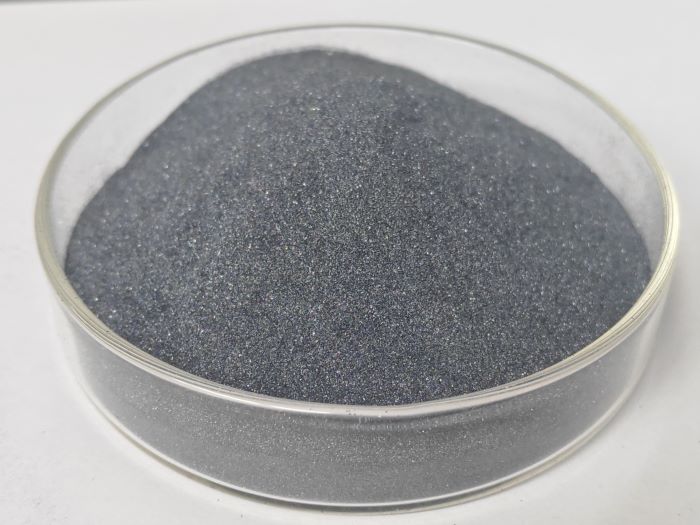

0-0.5mm Black SIC 98% for ceramics

Product Introduction

0-0.5mm Black Silicon Carbide (SiC) 98% is a premium-grade raw material specifically engineered for the advanced ceramics industry. With a guaranteed purity of 98% SiC and a controlled particle size distribution from fine powder up to 0.5mm, this product is an essential additive for enhancing the mechanical and thermal properties of high-performance ceramic composites and refractories.

This high-purity Black SiC is synthesized at extreme temperatures in electric resistance furnaces, resulting in crystals renowned for their exceptional hardness (second only to diamond and boron carbide), outstanding thermal conductivity, and superior chemical inertness. The specified particle range ensures optimal packing and integration within ceramic matrices.

TYPICAL CHEMICAL ANALISIS [%]:

| SiC | Fe2O3 | F.C |

| 98.0-99.5 | 0.05-0.10 | 0.06-0.15 |

PHYSICAL PROPERTIES

| Maximum service temperature (℃) | Specific Gravity g/cm3 | Melting Point (°C) | Mohs Hardness |

| 1900 | 3.90min | 2250 | 9.15 |

Key Features & Advantages for Ceramics:

Reinforcement & Toughening: Acts as a potent reinforcing phase, dramatically increasing the fracture toughness, hardness, and wear resistance of ceramic bodies, mitigating their inherent brittleness.

Enhanced Thermal Properties: Improves thermal shock resistance and thermal conductivity of the final ceramic component, which is critical for applications involving rapid temperature cycles.

High Purity (98%): Minimizes the introduction of unwanted metallic impurities (like free iron, silica, or alumina) that could compromise sintering behavior, high-temperature stability, or electrical properties of the ceramic.

Controlled Grain Size (0-0.5mm): Offers versatility for formulation. Finer particles integrate seamlessly for uniform reinforcement, while coarser grains can be used for specific structural or abrasive purposes within the ceramic.

Primary Applications in Ceramics:

Advanced Structural Ceramics: Reinforcement additive for silicon carbide (SiC-SiC), alumina (Al₂O₃), and other oxide or nitride matrix composites used in wear parts, armor, and cutting tools.

Refractory Ceramics: Key component in high-performance refractories for kiln furniture (setter plates, saggers), blast furnace linings, and non-ferrous metal handling, offering superior slag resistance and spalling resistance.

Functional Ceramics: Used in specialized ceramics requiring combined mechanical strength and thermal management.

Reaction-Bonded Silicon Carbide (RBSC): Serves as the aggregate foundation in the production of RBSC components.

Engineered to meet the stringent demands of modern ceramic engineering, this Black SiC 98% is the trusted choice for manufacturers seeking to develop stronger, more durable, and more reliable ceramic products for the most challenging industrial environments.