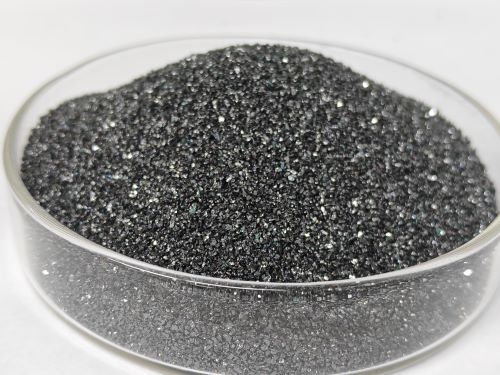

Product Paramenters

Black Silicon Carbide (Standard : GB/T2480-2008) | ||||

Usage | Black Sic For vitrified wheels/sanding belt | Black Sic For bonded abrasive | Black Sic For flap discs by hand | |

Type& Grade | C | C-B | C-P | |

NO | Grit No | Chemical composition (%) | ||

SiC (≥) | F.C. (≤) | Fe2O3(≤) | ||

C | F4-F90 P12-P100 | 98.50 | 0.2 | 0.4 |

F100-F150 P120-P150 | 98.10 | 0.25 | 0.5 | |

F180-F220 P180-P220 | 97.20 | 0.3 | 0.55 | |

F230-F280 P240-P360 | 97.20 | 0.3 | 0.55 | |

F320-F500 P400-P1000 | 97.00 | 0.35 | 0.6 | |

F600-F800 P1200-P1500 | 96.50 | 0.4 | 0.6 | |

F1000-F1200 P2000-P2500 | 95.50 | 0.5 | 0.7 | |

C-B&C-P | F4-F90 P12-P100 | 98.10 | 0.25 | 0.5 |

F100-F150 P120-P150 | 97.60 | 0.3 | 0.6 | |

F180-F220 P180-P220 | 96.70 | 0.35 | 0.65 | |

F230-F280 P240-P360 | 96.70 | 0.35 | 0.65 | |

F320-F500 P400-P1000 | 96.50 | 0.4 | 0.7 | |

F600-F800 P1200-P1500 | 96.00 | 0.45 | 0.7 | |

F1000-F1200 P2000-P2500 | 95.00 | 0.55 | 0.8 | |

For refractory: Refractory media for casting or metallurgical linings ,Technical Ceramics.

For new-type application: Heat exchangers ,Semiconductor process equipment , Liquid filtration.