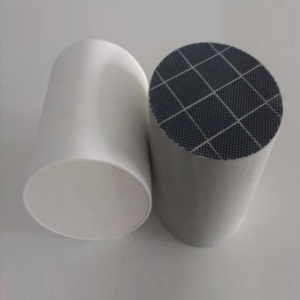

Application of 400-mesh green silicon carbide micropowder in GPF particle capture

With the increasing stringency of global automotive emission regulations, the Gasoline Particulate Filter (GPF) has become a critical after-treatment technology for controlling particulate matter (PM) emissions. Porous ceramic membranes, recognized for their excellent high-temperature resistance, chemical stability, and tunable pore structures, are considered ideal materials for GPF substrates and filtering layers. Among various technical pathways to enhance ceramic membrane performance, the introduction of functional micropowders as pore-forming agents or structural reinforcement phases has garnered significant attention. This article explores the application potential and advantages of 400-mesh green silicon carbide (SiC) micropowder in ceramic membrane GPFs for particle capture.

1. Material Properties Aligning with Application Demands

400-mesh green silicon carbide micropowder, with a particle size distribution of approximately 20-40 micrometers, possesses high hardness, high thermal conductivity, excellent thermal stability, and chemical inertness. These properties align perfectly with the harsh operating environment of GPFs, which involves high temperatures, high-velocity exhaust gas冲刷, and complex chemical atmospheres. Incorporating this micropowder into a ceramic membrane matrix (e.g., cordierite, SiC, or alumina-based) serves multiple purposes. Firstly, as a rigid pore-forming agent, the green SiC micropowder can create well-connected micrometer-sized pores after sintering, effectively constructing tortuous filtration channels and enhancing deep-bed filtration efficiency. Secondly, its hard particles can act as a “skeleton,” reinforcing the mechanical strength and thermal shock resistance of the composite ceramic membrane, thereby preventing crack formation due to thermal stress during frequent regeneration cycles.

2. Optimizing the Balance Between Filtration Efficiency and Pressure Drop

A core challenge for GPFs is achieving high capture efficiency for sub-micrometer soot particles while maintaining low exhaust backpressure. The introduction of 400-mesh green SiC micropowder, by enabling precise tuning of the ceramic membrane’s microstructure, helps address this矛盾. By adjusting the micropowder’s addition ratio and dispersion process, the size distribution and tortuosity of internal pores can be precisely controlled. This facilitates the formation of a graded pore structure, where larger particles are intercepted on the surface layer, and finer particles are captured via deep-bed filtration within the membrane. This approach can achieve capture efficiencies exceeding 99%. Simultaneously, the uniform and interconnected pore network reduces airflow resistance, maintaining a lower pressure drop, which minimizes the impact on engine performance and fuel economy.

3. Enhancing Durability and Regeneration Characteristics

GPFs require periodic regeneration through high-temperature combustion of accumulated particles. The high thermal conductivity of green SiC micropowder (approximately 100 W/m·K) facilitates rapid and uniform heat distribution within the filter body. This promotes the oxidation and combustion of soot particles, prevents localized overheating, thereby improving regeneration efficiency and reducing the risk of thermal stress damage. Its chemical inertness also ensures long-term material stability in complex exhaust environments containing oxygen, sulfur, phosphorus, etc., extending the GPF’s service life.

4. Application Prospects and Challenges

The application of 400-mesh green SiC micropowder in ceramic membrane GPFs is primarily realized through processes such as slurry impregnation, spraying, or direct incorporation into the green body for co-sintering. However, its large-scale adoption still faces challenges: first, cost control of the green SiC micropowder; second, the need to optimize the interface bonding between the micropowder and the ceramic matrix to prevent micro-crack formation under long-term thermal cycling; and third, the requirement for further research into the quantitative impact of the micropowder’s morphology and gradation on filtration performance.

Conclusion

In summary, 400-mesh green silicon carbide micropowder demonstrates significant advantages in optimizing the filtration accuracy, pressure drop characteristics, mechanical strength, and thermal management of ceramic membrane GPFs, owing to its unique physical and chemical properties. It serves not only as a functional pore-forming agent but also as a key reinforcing phase that enhances overall material performance. With continuous advancements in material preparation and coating technologies, green silicon carbide micropowder holds broad prospects in the development and application of high-efficiency, durable GPFs. It is poised to provide a vital material solution for meeting increasingly stringent emission standards.