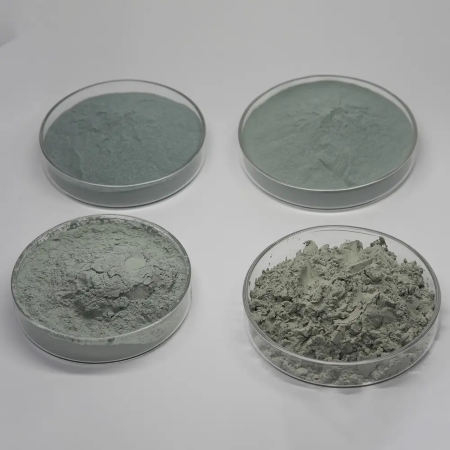

400# green silicon carbide powder for ceramic membrane GPF particulate filters

- Optimal Pore Creation & Structure: The sharp, angular grains are ideal for precise pore-forming and microstructure engineering within the ceramic membrane. This results in a perfectly controlled porosity and pore size distribution, essential for high filtration efficiency (>95% for PM 2.5/10) and optimal balance between soot capture and exhaust backpressure.

- Enhanced Membrane Strength: Incorporating this high-hardness material into the ceramic matrix significantly improves the mechanical strength and fracture toughness of the sintered filter. This enhances durability against thermal shocks, mechanical vibrations, and regeneration cycles, extending the filter’s service life.

- Superior Processing Performance: Used as a abrasive media for lapping and polishing, it provides an excellent surface finish on filter channels. This improves flow characteristics and facilitates more uniform soot accumulation and regeneration.

- High-Temperature Stability: Silicon carbide maintains its integrity and properties at the extreme temperatures (often exceeding 1000°C) encountered during filter regeneration, preventing degradation of the filter structure.

- Batch Consistency: Rigorous grading and quality control guarantee uniform particle size distribution from batch to batch. This consistency is critical for repeatable manufacturing processes, yielding GPFs with identical high-performance characteristics.

- As a Pore-Forming Agent: Mixed into the ceramic slurry (typically with cordierite or silicon carbide as the base material), it burns out during sintering, leaving behind a network of interconnected, size-controlled pores.

- As a Precision Abrasive: For machining, lapping, and polishing the filter’s honeycomb structure to exact dimensional tolerances and smooth surface finishes, ensuring optimal fluid dynamics.