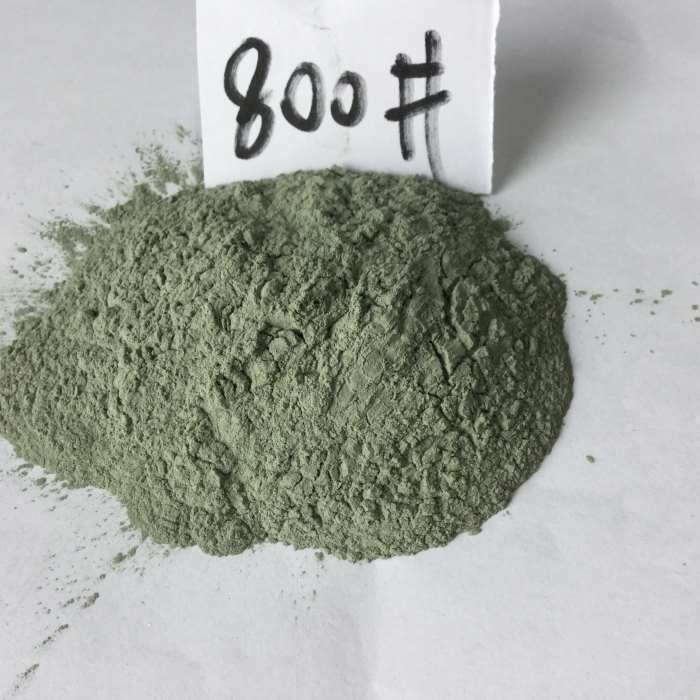

Green Silicon Carbide Powder 800#1000# for UV Coating

Superior Abrasion Resistance for Demanding UV-Cured Finishes

Our Green Silicon Carbide Powder in 800# and 1000# grits represents the pinnacle of high-performance micro-abrasives specifically engineered for the UV coating industry. Renowned for its exceptional hardness, sharp fracture, and chemical purity, this premium additive is the definitive solution for enhancing the durability, aesthetic quality, and functional performance of your UV-curable formulations.

Key Features & Benefits:

Unmatched Hardness & Wear Resistance: With a Mohs hardness of 9.5, second only to diamond, green silicon carbide significantly increases the scratch, abrasion, and mar resistance of cured UV coatings. This extends the product’s lifecycle, even in high-traffic applications, ensuring a pristine appearance for longer.

Exceptional Thermal Conductivity & Stability: Its high thermal conductivity helps dissip heat efficiently during the rapid UV curing process, minimizing thermal stress and ensuring a uniform, flawless cure. This property is crucial for maintaining coating integrity and preventing defects.

High Purity & Consistent Particle Size: Our powder is meticulously processed and classified to ensure a consistent, narrowly distributed particle size (800# ~12.6 µm / 1000# ~10.3 µm). This uniformity guarantees predictable viscosity modification, smooth application, and a consistent matte finish without surface imperfections.

Excellent Dispersion & Compatibility: The angular shape and clean surface of the particles allow for excellent dispersion within various UV resin matrices (e.g., acrylics, epoxies). This results in stable suspensions, preventing settling and ensuring homogenous performance throughout the application process.

PHYSICAL PROPERTIES

Specific Weight 3.95 g/ cm3 Mohs Hardness 9.5 Maximum service temperature 1900℃ Melting Point 2250℃ TTYPICAL CHEMICAL ANALISIS [%]

SiC Fe2O3 F.C F.Si SiO2 LOI 98.0-99.5 ≤0.15 ≤0.30 ≤0.40 ≤0.70 < 0.09 APARTICLE SIZE DISTRIBUTION

CHAPTER Ⅰ(JIS STANDARD)

Size DO(um) D3(um) D50(um) D94(um) #240 ≤127 ≤103 57.0±3.0 ≥40 #280 ≤112 ≤87 48.0±3.0 ≥33 #320 ≤98 ≤74 40.0±2.5 ≥27 #360 ≤86 ≤66 35.0±2.0 ≥23 #400 ≤75 ≤58 30.0±2.0 ≥20 #500 ≤63 ≤50 25.0±2.0 ≥16 #600 ≤53 ≤41 20.0±1.5 ≥13 #700 ≤45 ≤37 17.0±1.5 ≥11 #800 ≤38 ≤31 14.0±1.0 ≥9.0 #1000 ≤32 ≤27 11.5±1.0 ≥7.0 #1200 ≤27 ≤23 9.5±0.8 ≥5.5 #1500 ≤23 ≤20 8.0±0.6 ≥4.5 #2000 ≤19 ≤17 6.7±0.6 ≥4.0 #2500 ≤16 ≤14 5.5±0.5 ≥3.0 #3000 ≤13 ≤11 4.0±0.5 ≥2.0 #4000 ≤11 ≤8.0 3.0±0.4 ≥1.8 #6000 ≤8.0 ≤5.0 2.0±0.4 ≥0.8 #8000 ≤6.0 ≤3.5 1.2±0.3 ≥0.6 CHAPTER Ⅱ(FEPA STANDARD)

Size D3(um) D50(um) D94(um) F230 <82 53.0±3.0 >34 F240 <70 44.5±2.0 >28 F280 <59 36.5±1.5 >22 F320 <49 29.2±1.5 >16.5 F360 <40 22.8±1.5 >12 F400 <32 17.3±1.0 >8 F500 <25 12.8±1.0 >5 F600 <19 9.3±1.0 >3 F800 <14 6.5±1.0 >2 F1000 <10 4.5±0.8 >1 F1200 <7 3.0±0.5 >1(at 80%) F1500 <5 2.0±0.4 >0.8(at 80%) F2000 <3.5 1.2±0.3 >0.5(at 80%) Mainly Applications

-Bonded Abrasives and Coated abrasives

-Blasting,surface Treatment,Rust Removal

-Wet and dry blast media,grinding and polishing etc

-Floor/Wall laminates,Wear-resistant

-Ceramic products: Ceramic and Tiles,Ceramic filter plate,ceramic membrane etc

-Teflon painting etc

– Heat insulating material

-Grinding wheels,Cup wheels,Whetstone,polishing pads etc

-Used for crucibles, parts for kiln burning, mechanical seals, and parts materials to produce semiconductors