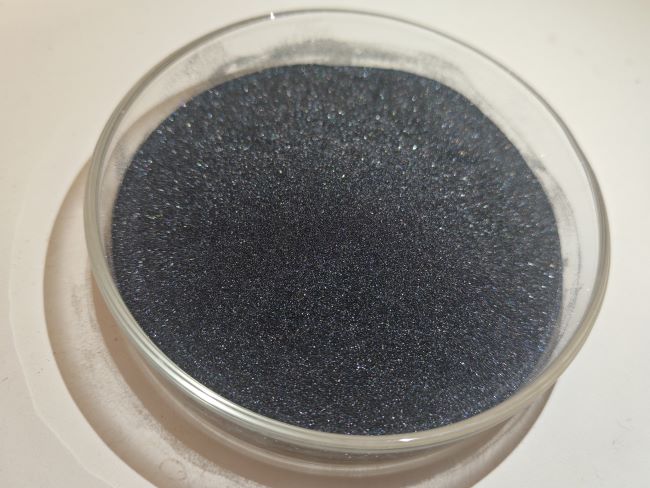

Black Silicon Carbide powder #220 for Wear-resistant coating

Superior Abrasion Resistance for Demanding Applications

Black Silicon Carbide (SiC) Powder #220 is a high-performance abrasive material designed to enhance the durability and wear resistance of coatings. With its exceptional hardness (9.5 on the Mohs scale) and sharp-edged particles, it is an ideal additive for wear-resistant coatings used in industrial, automotive, and aerospace applications.

Key Features & Benefits

Exceptional Hardness & Wear Resistance – Silicon carbide is one of the hardest synthetic materials, significantly improving the lifespan of coatings exposed to friction, abrasion, and impact.

High Thermal Conductivity & Chemical Stability – Performs reliably in high-temperature and corrosive environments, maintaining coating integrity under extreme conditions.

Uniform Particle Size (#220 Grit) – Ensures consistent dispersion within coatings, providing even protection and smooth surface finishes.

Cost-Effective Solution – Extends the service life of coated components, reducing maintenance and replacement costs.

Applications

Black Silicon Carbide Powder #220 is widely used in:

Industrial Wear-Resistant Coatings – Protects machinery, pipelines, and mining equipment from abrasive wear.

Automotive & Aerospace Coatings – Enhances the durability of engine parts, brake systems, and turbine components.

Anti-Slip & Protective Coatings – Improves traction and wear resistance in flooring, marine, and heavy equipment applications.

Ceramic & Composite Coatings – Reinforces structural integrity in high-stress environments.

Why Choose Our Black Silicon Carbide Powder?

High Purity & Consistent Quality – Manufactured under strict quality control for optimal performance.

Customizable Solutions – Available in different grit sizes to meet specific coating requirements.

Global Supply & Technical Support – Reliable delivery and expert guidance for your coating applications.

Upgrade your wear-resistant coatings with Black Silicon Carbide Powder #220—the ultimate solution for long-lasting protection against abrasion and harsh conditions.

Contact us today for samples and pricing!