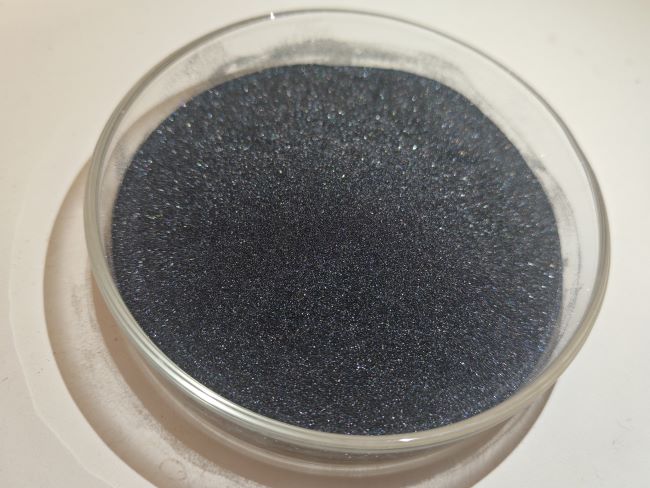

Black Silicon Carbide #280 Grit – Precision Abrasive for Intermediate Grinding & Finishing

Premium Performance for Demanding Applications

Black Silicon Carbide #280 grit represents the perfect balance between material removal and surface refinement. This medium-fine abrasive delivers exceptional results in precision grinding, finishing, and preparation for final polishing stages. With its superior hardness and consistent particle size, our SiC #280 is engineered for professionals who demand controlled aggressiveness with refined results.

Technical Specifications & Key Benefits

✔ Precise Grit Size (#280 / 46-58μm) – Ideal for intermediate smoothing operations

✔ Exceptional Hardness (9.5 Mohs) – 30% harder than aluminum oxide alternatives

✔ Angular Grain Structure – Maintains sharp cutting edges throughout use

✔ Thermal Conductivity – Reduces heat buildup during processing

✔ Chemical Stability – Suitable for wet or dry applications

Optimal Applications

Metal Fabrication & Finishing

Pre-polish preparation for stainless steel components

Deburring precision machined parts

Surface conditioning before electroplating

Aerospace component finishing

Stone & Glass Working

Intermediate polishing of granite and marble

Lapidary work on hard gemstones

Glass edge refinement

Terrazzo surface preparation

Specialized Industrial Uses

Composite material finishing

Ceramic component processing

Refractory material shaping

Automotive restoration work

Available Product Forms

Loose abrasive powder for manual applications

Bonded abrasives (wheels, sticks, blocks)

Coated abrasives (belts, discs, sheets)

Slurry formulations for machine processing

Competitive Advantages

• Faster cutting action than comparable alumina products

• More consistent results than standard silicon carbide

• Lower consumption rates due to enhanced durability

• Reduced loading in bonded applications

Quality Assurance

✓ Laser particle size analysis for each batch

✓ Magnetic separation to remove metallic impurities

✓ ISO 9001 certified manufacturing process

✓ Custom gradations available

Ordering Options & Support

Available in 1kg, 5kg, 25kg, and bulk packaging with flexible shipping solutions. Our technical team provides:

• Application recommendations

• Process optimization guidance

• Custom formulation services

Request your free sample today to experience the Black SiC #280 difference in your production process.