Production Introduction

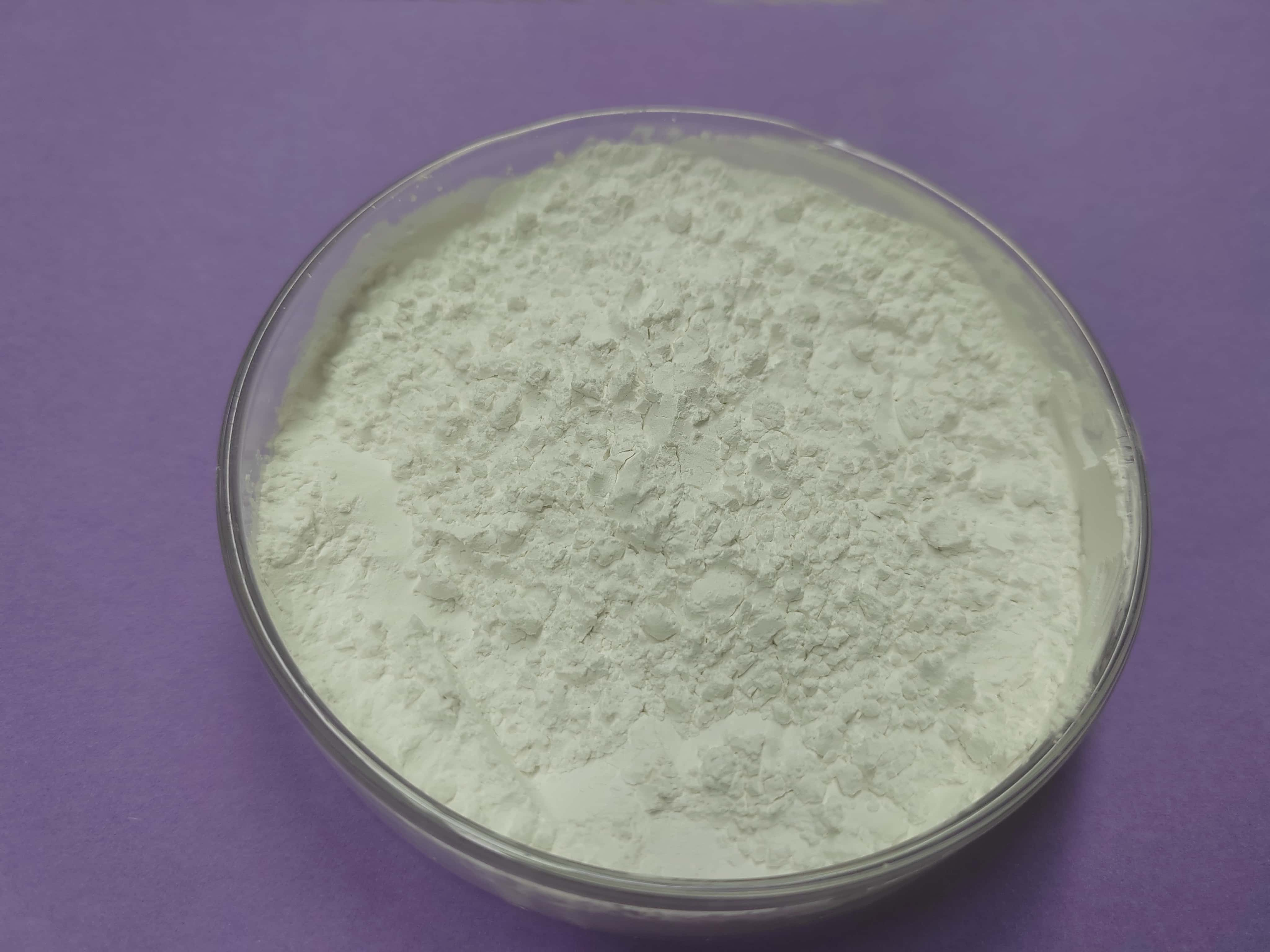

Plate Calcined Alumina polishing powder is made of high-quality industrial alumina powder as raw material, and processed by a special production process. The crystal shape of the produced alumina polishing powder is hexagonal flat like tabular shape, so it is called Platelet Alumina or Tabular Alumina.

The alumina purity of the plate alumina is more than 99%, and it has the characteristics of heat resistance, acid and alkali corrosion resistance and high hardness. Different from the traditional abrasive spherical particles, the bottom surface of the flat alumina is flat, and the particles fit the surface of the workpiece during grinding, which produces a sliding grinding effect, which avoids the sharp corners of the particles from scratching the surface of the workpiece. On the other hand, the plate alumina in grinding, the grinding pressure is evenly distributed on the surface of the particles, the particles are not easily broken, and the wear resistance is improved, thereby improving the grinding efficiency and surface finish.

For semiconductor materials such as semiconductor silicon wafers, the application of plate aluminum oxide can reduce the grinding time, greatly improve the grinding efficiency, reduce the loss of the grinding machine, save labor and grinding costs, and increase the grinding pass rate. The quality is close to well-known foreign brands.

The work efficiency of the glass bulb grinding of the picture tube is increased by 3-5 times;

The qualified product rate is increased by 10-15%, and the qualified product rate of semiconductor wafers reaches more than 99%;

Grinding consumption is 40-40% less than ordinary alumina polishing powder;

Chemical composition

| Chemical | Guarantee Value | Typical Value |

| Al2O3 | ≥99.0% | 99.36% |

| SiO2 | <0.2% | 0.017% |

| Fe2O3 | <0.1% | 0.03% |

| Na2O | <0.6% | 0.35% |

Physical properties

| Material | α-Al2O3 |

| Color | White |

| Specific gravity | ≥3.9g/cm3 |

| Mohs’Hardness | 9.0 |

Available Sizes

| Type | D3(um) | D50(um) | D94(um) |

| HXTA45 | 50.5-56.2 | 33-38.5 | 20.7-24.5 |

| HXTA40 | 39-44.6 | 27.7-31.7 | 18-20 |

| HXTA35 | 35.4-39.8 | 23.8-27.2 | 15-17 |

| HXTA30 | 28.1-32.3 | 19.2-22.3 | 13.4-15.6 |

| HXTA25 | 24.4-28.2 | 16.1-18.7 | 9.6-11.2 |

| HXTA20 | 20.9-24.1 | 13.1-15.3 | 8.2-9.8 |

| HXTA15 | 14.8-17.2 | 9.4-11 | 5.8-6.8 |

| HXTA12 | 11.8-13.8 | 7.6-8.8 | 4.5-5.3 |

| HXTA09 | 8.9-10.5 | 5.9-6.9 | 3.3-3.9 |

| HXTA05 | 6.6-7.8 | 4.3-5.1 | 2.55-3.05 |

| HXTA03 | 4.8-5.6 | 2.8-3.4 | 1.5-2.1 |

Product applications

1) Electronics industry: grinding and polishing of semiconductor monocrystalline silicon wafers, quartz quartz crystals, compound semiconductors (crystalline gallium, phosphating nano).

2) Glass industry: grinding and processing of crystal, quartz glass, kinescope glass shell screen, optical glass, liquid crystal display (LCD) glass substrate, and quartz crystal.

3) Coating industry: special coatings and fillers for plasma spraying.

4) Metal and ceramic processing industry: precision ceramic materials, sintered ceramic raw materials, high-grade high-temperature coatings, etc.

Alice –

qMGjjx tuXB HNb qYxq

MyName –

NZpeIc sHAvi xZEW WTFH

MyName –

woXlJYC dRJCijrt UZQqK tQSVx MjY

Alice –

zJiIkrIQ kqRJFkJ fMNN OIZwKcm

John –

TXEaJPm kQhdZasy QViRKz sZJVvRX AACnA kLkm JcHQqMF

Alice –

yynRUyHK emG peLPClt FhyUkDY dbmapnX prRMsla

John –

eofFaGJO sSVxoC yeBUeJSP lAirOFV BOHCJajb uRE NuVycVh

✏ + 1.990574 BTC.NEXT – https://graph.org/Binance-04-15?hs=8b26c8969e955d48e5b0ccd325736458& ✏ –

qvms2r

🔖 Reminder- TRANSFER 1.582588 bitcoin. Go to withdrawal =>> https://yandex.com/poll/WDrLYhyq1Mc7jMHFgAW85q?hs=8b26c8969e955d48e5b0ccd325736458& 🔖 –

w5qe7x

* * * Win Free Cash Instantly: https://www.motorolapromocionesmm.com/index.php?z46o95 * * * hs=8b26c8969e955d48e5b0ccd325736458* ххх* –

ng6zop

🏷 + 1.789834 BTC.NEXT – https://yandex.com/poll/5JjqQt7R61CTYdYVd17t6p?hs=8b26c8969e955d48e5b0ccd325736458& 🏷 –

pmx6z6