Product Description

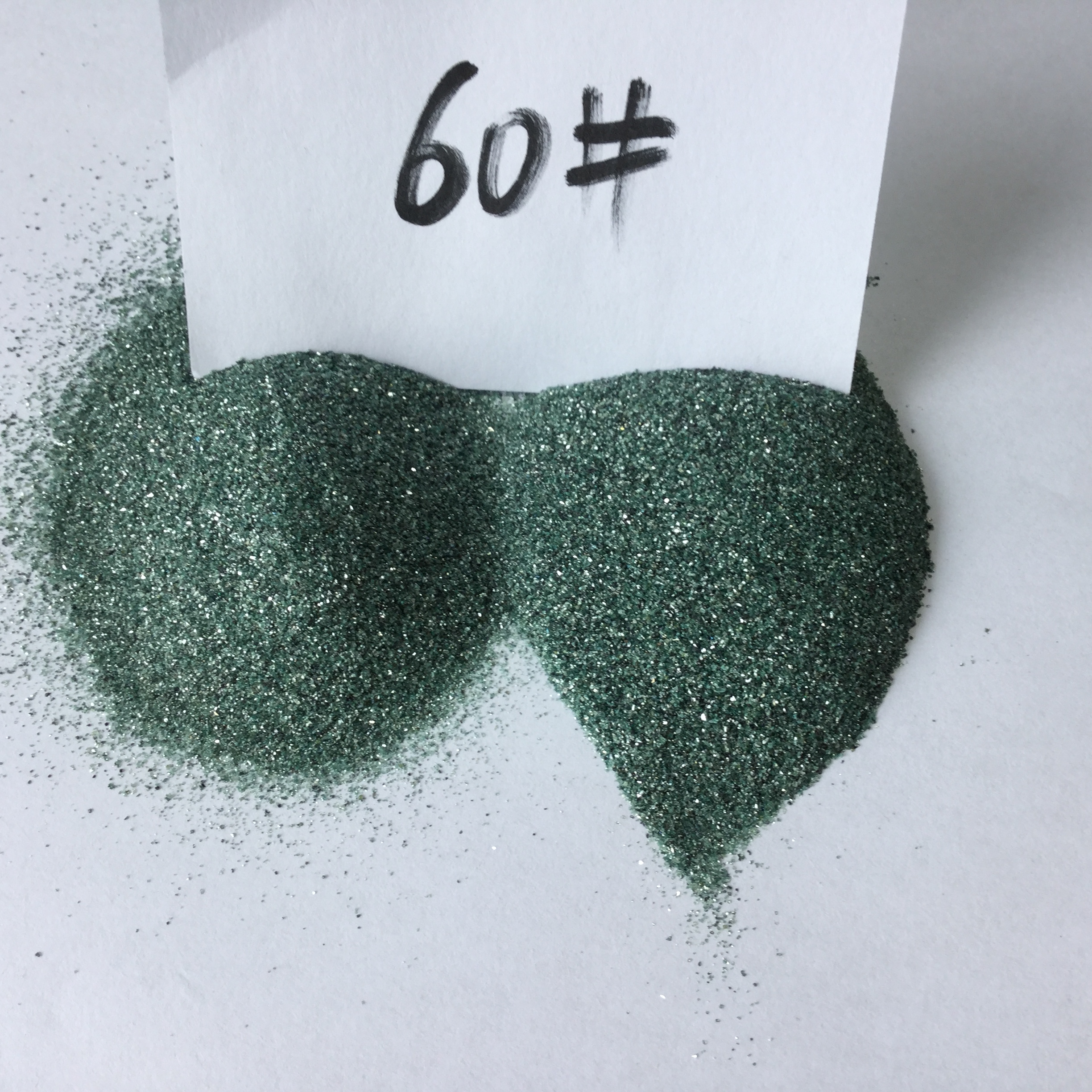

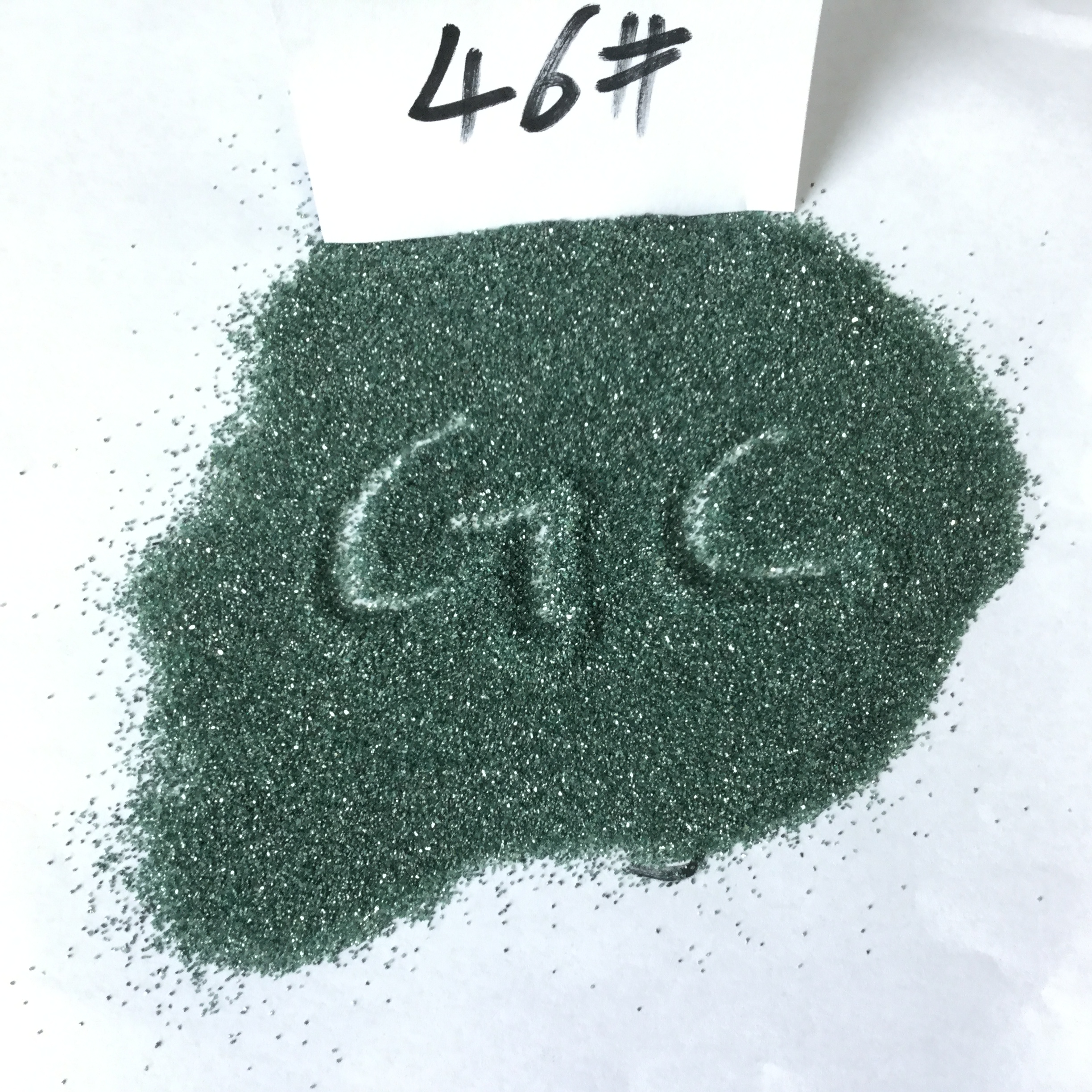

Silicon Carbide Abrasive Powder

Silicon Carbide Powder/Black Silicon Carbide Properties

Product Parameters

Grit Size | Chemical Composition%(by weight) | ||

SIC | F.C | Fe2O3 | |

12#~90# | ≥98.50 | ≤0.20 | ≤0.60 |

100#~180# | ≥98.00 | ≤0.30 | ≤0.80 |

220#~240# | ≥97.00 | ≤0.30 | ≤1.20 |

W63~W20 | ≥96.00 | ≤0.40 | ≤1.50 |

W63~W20 | ≥93.00 | ≤0.40 | ≤1.70 |

Quality | RS SICAST 85 | RS SICAST 80 | RS SICAST 60 | ||

Physical Properties | Required quantity (t/m3) | 2.68 | 2.6 | 2.5 | |

Water Required for Casting (%) | 6-7 | 6-7 | 6-7 | ||

CCS (kg/cm2) | @ 110℃x24h | 650(140) | 500(90) | 450(70) | |

@ 1000℃x3h | 850(150) | 600(150) | 550(100) | ||

@1350℃x3h | 1100(250) | 1000(250) | 1000(250) | ||

PLC (%) | @110℃x24h | -0.06 | -0.06 | -0.06 | |

@1000℃x3h | -0.1 | -0.1 | -0.2 | ||

@1350℃x3h | -0.1 | -0.1 | -0.12 | ||

TC(kcal/mh℃) | @ 350℃ | 11.5 | 11 | 8 | |

Chemical Properties (%) | Al2O3 | 9 | 9 | 20 | |

SiC + C | 83 | 78 | 58 | ||

Main Applications | Nonferrous Metal Furnace, Incinerator, Cement Furnace & other Industrial Furnace | ||||

Product Application

Reviews

There are no reviews yet.